Product

Product

WT 5935C-500-A90 Thermal pad

WT 5935C-500-A90 High thermal conductivity pad uses the carbon fiber nanotube oriented tableting technology developed by WT. It is superior to traditional thermal pads in thermal conductivity and product elasticity. The product is made of silicone rubber filled with carbon-based materials.

▶ Typical Application

● High end equipments and automotive electronic coolings and heating components, such as electronic devices, semiconductor memory devices, etc

● General-purpose inverters, Medical equipments, Digital Signal Controllers

● Automotive electronics, such as on-board cameras, motor control units, automotive navigation, automotive lighting (LED), Dynamic Stability Controls

● Laser HUD light source

● Consumer microelectronics and hand held electronic devices

● Base station, IGBT modules

▶ Parameter Index

Index | Test Standards | Data |

Color | / | Black |

Thickness (mm) | ASTM D374 | 0.2~5.0 |

Thermal conductivity (W/(m·K)) | ASTM D5470 | 50 |

Hardness (Shore A) | ASTM D2240 | 90 |

Density (g/cm³) | ASTM D792 | 2.5 |

Breakdown voltage (kV/mm) | ASTM D149 | <0.1 |

D3-D10 | / | <500ppm |

Temperature range (℃) | / | -50~150 |

Flame retardant rating | UL94 | V-0 |

Customized options | Double sided non-stick/single-sided adhesive/double-sided sticky | |

▶ Function and Characteristics

● High thermal interface performance: 45~55 W/(m·K)

● High flexibility: can be perfectly embed in uneven interface

● High applicability: stable performance under -50~150℃

● Excellent flame performance: meet UL94-V0 level

● RoHS, REACH comliance

● Low precipitation oil

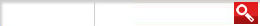

▶ Dimension

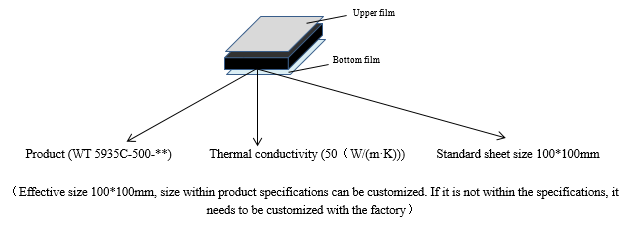

▶ Comparison Test of Appearance of Compressed 50% High-temperature Oil Separation

(1) Attach a layer of filter paper to the top and bottom of the conventional WT5935C-500-85 and WT5935C-500-A90 (low oil separation) thermal pads, and use the filter paper to evenly adhere them to both sides of the product. Then, use a fixture to clamp and compress the sample to about 50% and maintain it;

(2) Place the fixture with the sample in a constant temperature drying oven at 120 ℃ and maintain it for 48 hours;

(3) After 48 hours, take it out and leave it at room temperature for 30 minutes. Then, remove the filter paper and observe the oil print under the measuring display mirror.

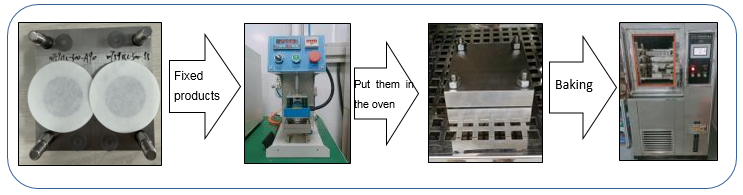

▶ Oil Appearance Comparison Test Diagram

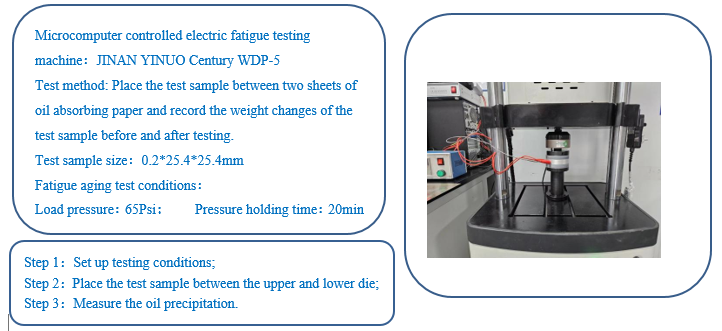

▶ Testing Method and Data for Compressed Oil Precipitation

Oil Precipitation Test Results | |||||

Test sample | Thickness/mm | Dimension/mm | Weight before testing/g | Weight after testing/g | Oil precipitation rate% |

WT5935C-500-85 | 0.2 | 25.4*25.4 | 0.243 | 0.242 | 0.4 |

WT5935C-500-A90 | 0.2 | 25.4*25.4 | 0.25 | 0.25 | 0.0 |

Result | The oil precipitation rate of WT5935C-500-A90 is 0%, which is lower than that of the conventional WT5935C-500-85. | ||||

Remarks | The experimental data is for reference only, and the actual application shall prevail. | ||||

▶ Storage Conditions

Temperature: 0–35°C,Relative Humidity: 35%–65%

Product remains usable at any time under normal storage conditions.

Shelf life: 12 months. Avoid stacking heavy loads or applying excessive pressure during storage.

▶ Remarks

Waermtimo reserves the final amendment rights to product specifications and documentation.