Product

Product

WT5922-501AB Thermal Elastomer

WT5922-501AB Two-Component Thermally Conductive Elastomer compound a dual-part system requiring precise 1:1 stoichiometric mixing ratio to form a high-thermal-conductivity encapsulant. upon thorough homogenization of Parts A/B, the mixture cures into a flexible elastomer that provides: dielectric isolation for electronic components, long-term reliable protection for sensitive circuitry across wide thermal/humidity excursions, compatibility with PC, PP, ABS, PVC substrates and metallic surfaces.

▶ Typical Application

● Automotive electronics, such as motor control units, drive modules

● Power Electronics Packaging Modules, such as silicon carbide modules, IGBT integrated modules, MOSFET integrated modules, LED integrated modules, industrial grade IPM modules, controllable silicon modules, diode modules, etc

● Power modules with high insulation and temperature resistance requirements, such as communication power supply module, high-voltage DC power supply module, special power supply modules, high-power converter/inverter module, etc

● Insulation protection of sensitive components and circuits in power electronic circuits, such as high-frequency transformers, connectors, sensors, electric heating parts, and circuit boards, for insulation and thermal sealing of products

▶ Parameter Index

Product specifications | |||

Test Item | Performance index | Test standard | |

Component A | Component B | ||

Color appearance | White fluid | Grey fluid | Visual |

Before curing | |||

Mixing ratio | 1:1 | NA | |

Viscosity(m Pa·s) | 35000 | 11500 | NA |

Curing time (min) | 80℃ <30min | NA | |

25℃ 60-480min | NA | ||

After curing | |||

Test Item | Unit | Performance index | Test standard |

Hardness | Shore A | 50 | ASTM D2240 |

Density | g/cm³ | 3.1 | ASTM D792 |

Tensile Strength | MPa | 0.6 | ASTM D412 |

Elongation | % | >30 | ASTM D412 |

Breakdown voltage strength | kV/mm | >10 | ASTM D149 |

Volume resistivity | Ω·cm | 1.0×1016 | ASTM D257 |

Temperature range | ℃ | -50~200 | NA |

Thermal conductivity | W/(m·K) | 5.2 | ASTM D5470 |

Flammability rating | / | V-0 | UL 94 |

Curing time varies with temperature, humidity,potting thickness. Results are indicative only. Actual parameters require validation under field conditions | |||

▶ Function and Characteristics

● Excellent curing stability

● Excellent potting operability and heat dissipation performance

● Excellent insulation properties, heat resistance, moisture resistance, cold resistance, impact

resistance

● Play the role of moisture-proof, shock-proof, dust-proof, anti-corrosion, anti-aging, etc

● Low viscosity, good fluidity, suitable for molding of complex electronic parts

● Extend the life of electronic accessories after application

● Excellent flame retardant performance: meet UL94-V0 level

● RoHS, REACH compliance

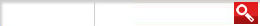

▶Salt spray test after curing

● Standard: ASTMB-117

● Salt spray test: NSS, ACSS

● Test temperature: 35℃±0.5℃。

● Pressurized air barrel:47℃±0.5℃。

● Spray method:

a. Bernut's principle absorbs salt water and then atomizes, the degree of atomization is uniform, and there is no phenomenon of blocking crystallization, which can ensure continuous testing.

b. The nozzle is made of tempered glass, and the spray volume and spray angle can be adjusted.

c. The spray volume is adjustable from 1 ~ 2ml/h (the standard of ml/80cm2/h requires testing for 16 hours to obtain the average volume).

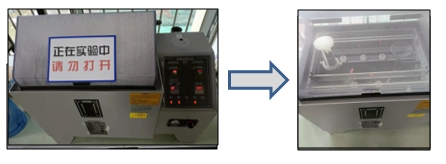

▶ Test picture after sample experiment (16H)

▶ Packaging Specification

1KG can, 5KG (small bucket), 25KG (big bucket)

▶ Precautions

● It is normal for the product to precipitate with the storage time. Before mixing, firstly mix components A and B fully and evenly.

● When mixing, make sure that component A and component B are weighed in a weight ratio of 1:1 and stirred evenly

● Avoid (containing nitrogen, phosphorus and sulfur) contamination of component B

● The mixed material should be poured into the product to be poured as soon as possible to prevent the material from thickening and poor fluidity in the later stage.

● Vacuum pumping is required before gluing, with a reference time of 5 minutes. The specific time is subject to the actual defoaming effect.

Waermtimo reserves the final amendment rights to product specifications and documentation.